The daily commitment of the Creativity & Design and Research & Development departments of FLEX is to transform ideas into concrete solutions

The continuous research for quality and the craftsmanship of made in Italy products has led the company to be active towards the needs of its customers . Flex offers a large collection of standard products and a broad vision of the customer's needs. This way of acting pushed the company to create an innovative production.

01 - project built on customer needs;

02 - uniqueness and customization of the Design;

03 - solutions that reflect the company's identity;

04 - align with socio-cultural evolution by offering innovative and potentially winning solutions;

05 - create of products designed and created to be rich in content and long lasting.

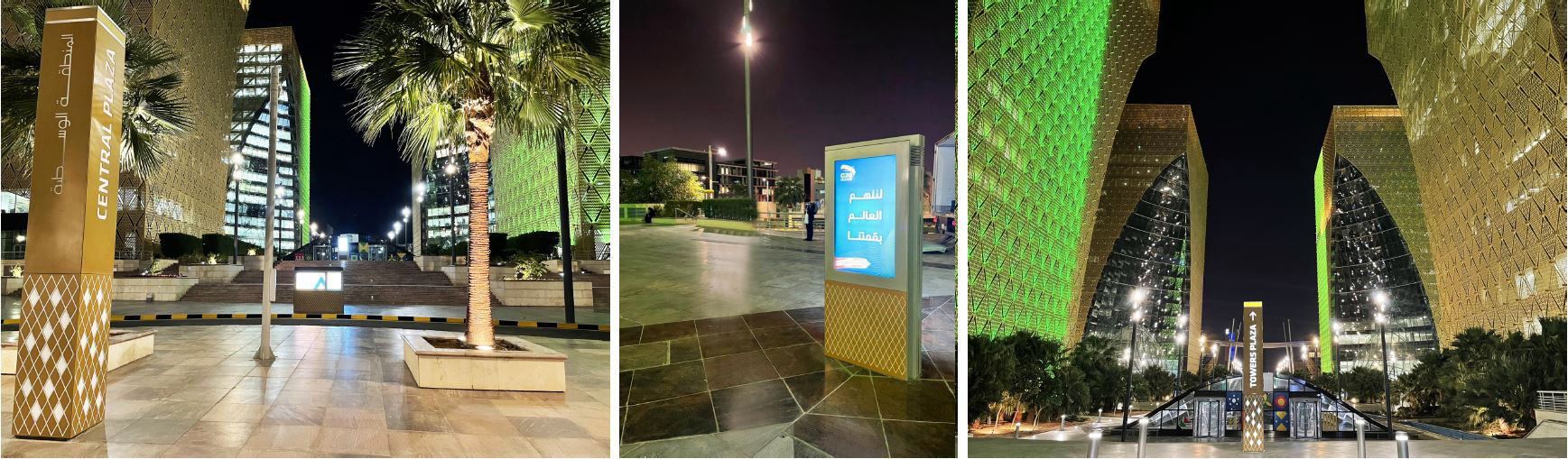

Flex products are born by listening to customers' needs with the purpose of creating something unique that perfectly suits to your requests For thirty years we have been offering customized solutions that can be integrated with the environment in which they are inserted. A Flex product is an experience that takes shape and communicates a message. Everything starts from an idea. Flex makes a careful analysis of the customer's requests. Then it conducts a study of the environment and a research for product specifications. The next step is the engineering which consists of a technical analysis of materials, finishes and details. This analysis is essential to proceed with the prototyping and the sampling of the product. The last stages are production and installation. Finally, we create a product with a refined, functional and robust design. These are features that have always distinguished Flex

Customer Needs

Collection of requests and customer needs to have a clear idea of the function of the product (informing, entertaining …) and defining the budget for the project.

Environmental Specifications

Collection of environmental information such as climate and temperature to get a clear idea of where the product will be placed (sun, outdoors, high humidity …)

Idea

Creative generation of ideas and hypothesis, free development of new concept and variations: creation, destruction and brand new solutions regeneration.

Focusing

Analysis of the hypothesis generated in the creative stage, selection of the most creative and effective ones, solutions evaluation. Choose.

Draft

Hand draw of the solutions, creativity and craftsmanship transposed on paper, concept sharpening.

Aesthetic and material hypothesis

Aesthetic analysis of the product with chromatic and design variations study, combined with a first evaluation of materials to be used.

Comparison and choice of the concept together with the customer.

Placement study

Environment and projects plan analysis for a specific identification of different placement situations and product use destinations.

Specific product variation

Product variant will be designed and engineered for each specific use destination and placement situation identified in the previous study.

Product design presentation

Designed product will be shown clarifying every technical specifications and use destinations to give a clear and effective answer to the client’s needs.

Product placement project presentation

Final product will be placed on client’s map with a complete and effective project that can satisfy final user needs.

Product project

presentation

Designed product will be engineered through professional 3D modelling software according to the most advanced production technologies.

Product placement projects presentation

Construction materials and several finishing, thickness and every technical details will be analyzed, calculated, estimated with high accuracy.

Product prototyping

Product will be prototyped with high precision and accuracy to be identical to the final production.

Sharpening of the product

Prototypes will be accurately analyzed and tested to identify, correct eventual defects and fix final products specifications.

Preliminary feasibility study

Preparation of the authorization request in compliance with local regulations

Preparation of authorization request to the superintendencies and

landscape reports where necessary

Authorization from third parties (Highways – Railways)

Authorization request by the property or by the condominium

Integrations to the institution of competence where requested

Collection of authorizations

Production and assembly

Final product will be fabricated and assembled with high attention to every detail and extreme care of the personalization.

Delivery and installation

Products will be shipped with the main international delivery vectors and installed by high specialized workers with company control and supervision.

HTML Website Builder